- #Lifting lug design spreadsheet .exe#

- #Lifting lug design spreadsheet manual#

- #Lifting lug design spreadsheet verification#

- #Lifting lug design spreadsheet code#

When lifting and turning a multi-million dollar tower there had better have been some sophisticated analysis done on every component of the lifting apparatus to ensure life safety and protection of the equipment.

#Lifting lug design spreadsheet code#

If left on the vessel during operation then they must meet the Code material requirements for nonpressure parts, UG-4(b).īut this doesn't mean that these lugs need not be "engineered". In this sense they are no different than any temporary clip added to facilitate handling during shop fabrication. See the instructions within the documentation for more details on performing this analysis.

#Lifting lug design spreadsheet manual#

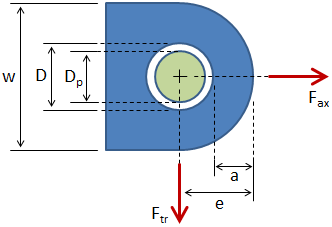

This calculator follows the Air Force Method as documented in the Stress Analysis Manual of the Air Force Flight Dynamics Laboratory (FDL). com (FREE) This spreadsheet consists of many segments regarding RCC aspects as. The Lug Analysis calculator allows for analysis of lifting lugs under axial, transverse, or oblique loading. Lifting lugs are a temporary attachment that may be removed from the shell before operation. lifting lug design calculations kamanafoundation com.

And hopefully no one will try to lift and move a pressurized vessel using temporary "lifting lugs". Such lugs are not intended as primary structural supports during operation of the vessel (if they were they would be support lugs). LIFTINGLUG - LIFTING LUG ANALYSIS Program Description: LIFTINGLUG is a spreadsheet program written in MS-Excel for the purpose of analysis of. Lifting lugs, however, are intended for temporary use during construction, erection, and placement of the vessel prior to operation. These loads from the support lugs are clearly included in UG-22 as loadings to be considered when designing the vessel. Thus the local stresses in the shell resulting from the support reactions must be combined with stresses resulting from pressure. Support lugs (as opposed to a support skirt, legs, saddles, etc) support the vessel during operation. Then I realized just what a can of worms are opened by this simple question.įirst, let's clarify if we're discussing lifting lugs or support lugs:

But I have to admit it did make me think for a bit. Please download LugCalc and review the documentation to learn more.Meteng, I respectfully disagree with your response. mec Engineering Spreadsheets- The site offers various mechanical and structural engineering calculations in Excel, including bolted and welded connections, bolt and screw verification, threaded holes and shafts, pin connection design, shaft and hub connection, general design tool for plate, beams and sections, lifting lug design, cylinders in pressure, Herts contact problems. ANSYS to STAAD converter: Visual basic application to generate a STAAD file containing. All designs, especially safety critical designs, should be verified and validated via other methods and physical testing before use. 1 Lug with Pinned Connection: ASME BTH-1 of 5 2 Description 3 65,000 W lb - Weight of the load 4 3 Nd - Design factor 5 Material: 6 SA-36 Material 7 36,000 Fy psi - Yield strength 8 58,000 Fu psi - Tensile strength 9 29,000,000 E psi - Modulus of elasticity 10 Dimensions: 11 2.000 Dh in - Hole diameter 12 8.000 w in - Width. Lift lug: Spreadsheet to design lift lugs per ASME lifting standard. In mechanical design, lug threshold estimates are considered a starting point. Two engineers can arrive at different solutions to the same problem using the same data. Lug analysis methods are estimates based upon historical testing captured in print publications. Now it is possible to select both the Metric (S.I.) and English. LugCalc operates in both US customary and metric unit systems. Updated Lifting Lug Design (v 3.0) spreadsheet in the Pin connections and lifting lugs category. The basic design of a lifting lug consists of the following four parts the design of lug plate, verifying the weld used to connect it to a shell or structure, checking the bearing stress at the pin-hole and confirming the end area of the lug. Typical uses of LugCalc include fittings, lifting lugs, actuator ends, and other structural connections. Lifting lug design is very critical and hence mostly done using FEA software. LugCalc provides the ability to batch process 1000’s of lug analysis calculations and automate the documentation process. LugCalc performs lug analysis calculations based upon the U.S.

#Lifting lug design spreadsheet .exe#

EXE application file format identified by our icon image. The spreadsheet you will purchase and receive is an excel file compiled in a.

#Lifting lug design spreadsheet verification#

What is LugCalc and what is the calculator used for? The Part 2 contains the new verification worksheets included in the version 2.0 (lifting padeyes with stiffening brackets and lugs with overlapping plate joint).

0 kommentar(er)

0 kommentar(er)